The state of lead exposure

Lead is toxic to multiple body systems and especially affects children, who are more vulnerable to lead exposure and its effects than adults. Globally, 1 in 3 children (about 815 million) are affected with estimated blood lead levels (BLLs) above 5 micrograms per decilitre (μg/dL). This level is considered a cause for action and is associated with decreased intelligence, behavioural difficulties, and learning problems.

While lead has been known to be toxic since ancient times, the scale of lead poisoning has previously gone unrecognised. Lead has been found in many sources, accounts for about 1% of the global disease burden, and economic losses of almost $1 trillion to the economies of low and middle-income countries (LMICs).

One major source of lead exposure since the 1920s was leaded petrol, which was only recently declared phased out worldwide in 2021. This milestone is estimated to prevent more than 1.2 million premature deaths per year, and BLLs have since greatly declined in high-income countries. However, for children and adults in LMICs, BLLs and lead exposures remain high, particularly in Africa and South Asia. Lead exposure exists in various sources, ranging from lead-based paints to cookware manufactured with scrap lead.

Why LEEP currently focuses on lead paint

LEEP’s mission is to reduce lead poisoning. We currently do so primarily by advocating for lead paint regulation in countries with large and growing burdens of lead poisoning from paint.

Lead paint is a significant source of lead exposure.

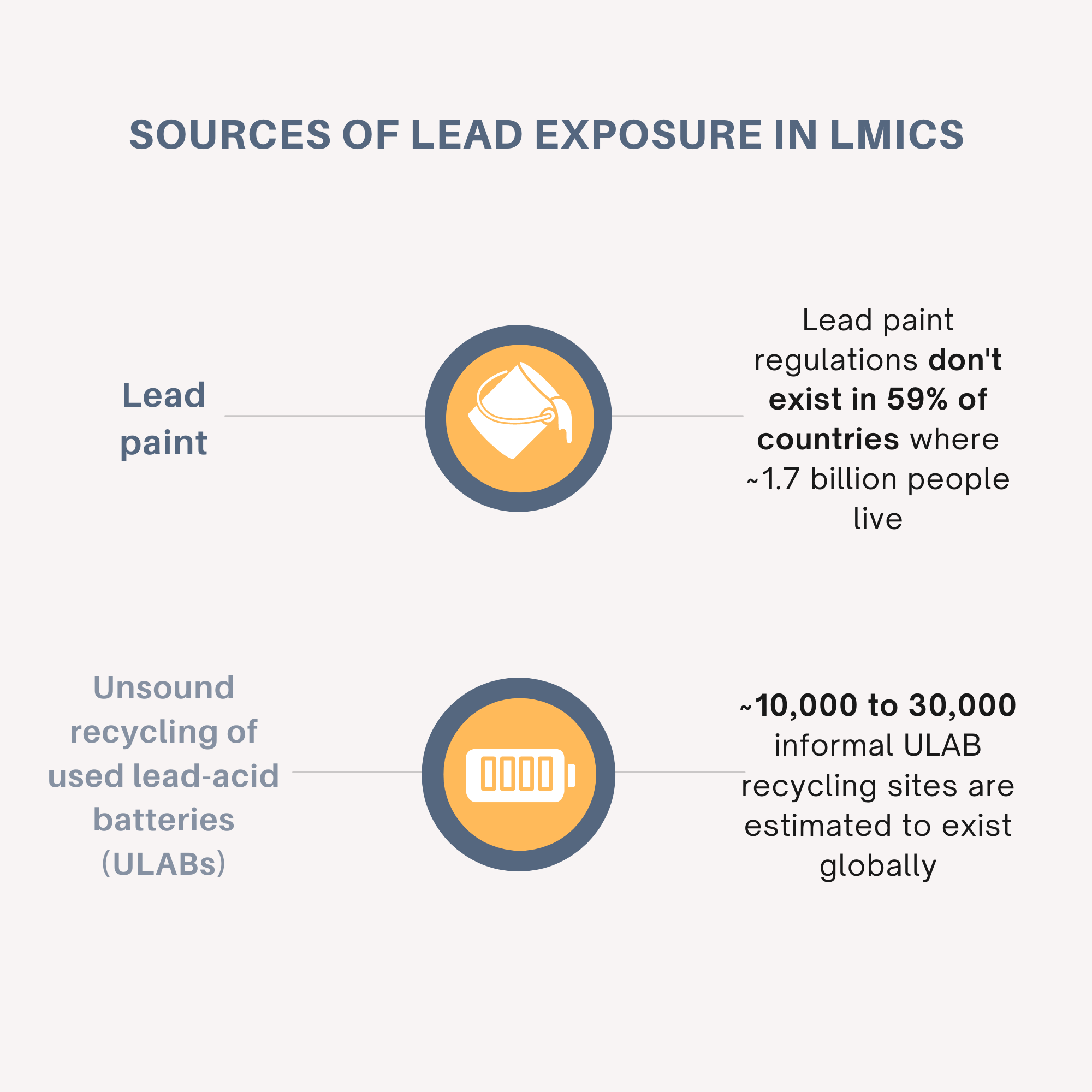

Lead paint is an important, widespread, low-level source of lead exposure found in many contexts, such as in homes and schools, on toys and playground equipment, or from occupational exposure. It becomes a source of exposure once it starts to degrade, flake, and release into dust, which young children are especially vulnerable to ingesting. High levels of lead in paint exist in at least 59 countries.

Lead paint regulation is relatively neglected.

While the Global Alliance to Eliminate Lead Paint and the International Pollutants Elimination Network (IPEN) are pushing to ensure all countries have regulations by 2030, regulations do not exist in 59% of countries where approximately 1.7 billion people live, and countries with regulations still experience problems in enforcing them. Further, much of the Alliance’s work has been funded through the Strategic Approach to International Chemicals Management – Global Environment Facility Project that will be ending in 2022, so the problem is likely to become even more neglected.

Lead paint regulation has a good track record.

NGOs have so far been successful in advocating for the introduction of new lead paint laws in 21 LMICs, and LEEP has so far had success in driving policy change in Malawi.

Further, lead paint regulation is a cost-effective intervention. While there are different ways to eliminate lead paint, there is broad agreement that introducing legally-binding regulation is the most effective way to reduce exposure to lead paint, and switching to unleaded paints is technically and economically viable for manufacturers. From our work in Malawi, we have tentatively estimated the cost of averting the loss of a full year’s health at $14, which compares favourably with other programs.

Other sources of lead exposure

While LEEP has so far focused on lead paint, we expect that other sources may also be promising to address. Currently, the distribution of the lead burden across these different sources is unclear and sources of lead exposure are not limited to those listed below.

Lead-acid batteries (ULABs)

Where it’s a problem

ULABs are generally found in cars, trucks, and other vehicles. Almost all of the lead in these batteries could be recycled, which decreases the need to mine lead. In the US and Europe, this recycling is generally regulated. However, in many LMICs, recycling activities are often conducted in informal, unlicensed, and illegal operations close to homes and schools, releasing toxic dust and fumes to workers not wearing protective equipment and the environment where the sites are located. For this reason, informal ULAB recycling sites can particularly be a problem for the communities in which they are carried out.

The scale of the problem

About 85% of lead used worldwide goes into the production of lead-acid batteries and an appraisal suggests as much as half of ULAB recycling ends up in the informal sector, where 10,000 to 30,000 informal ULAB recycling sites are estimated to exist globally, mostly in Africa, South Asia, and Southeast Asia. One estimate suggests that 6 to 16.8 million people may be exposed to lead in these sites.

The tractability of reducing this source

There currently exist guidelines for environmentally sound recycling that the Basel Action Network aims to enforce, but it isn’t clear how well these guidelines are being followed, and not many safeguards to lead contamination from ULAB recycling exist in the informal sector.

A major group that has been working on this problem is Pure Earth, who has highlighted protecting children in exposed communities through immediate treatment, environmental remediation, education awareness, and policy solutions.

Policy solutions for prevention appear most promising. These could include national ULAB collection systems and creation of incentives to return used batteries back into the formal system, such as regulation requiring manufacturers to buy back used batteries, fees on the manufacture or import of batteries that are returned on collection, reducing taxes on formal recycling, or direct subsidisation of formal collection. Some of these approaches appear to have been effective in Brazil.

Spices

Where it’s a problem

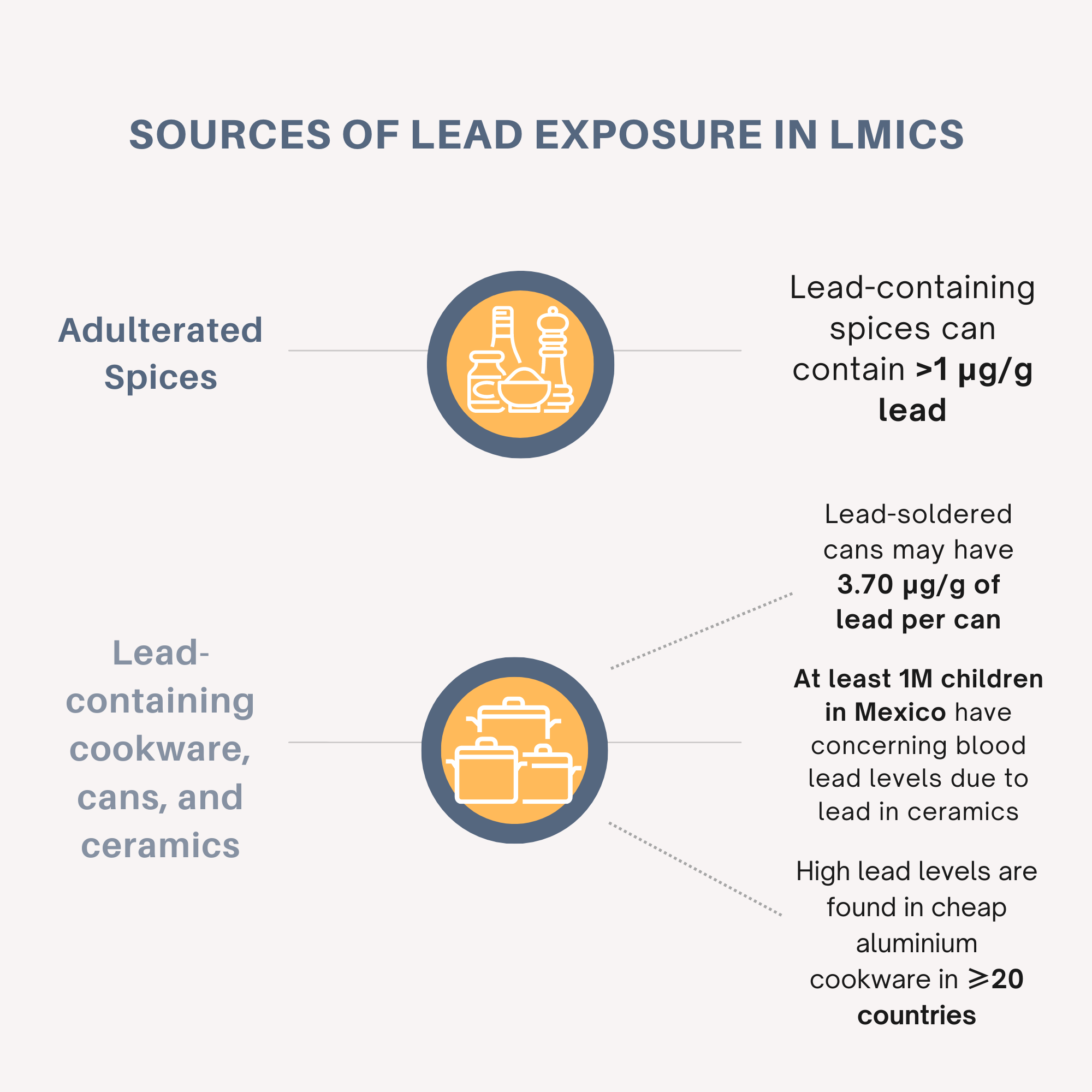

Spices can be intentionally “adulterated” with lead – being added to spices to enhance their colour or increase their weight – or inadvertently, because of poor processing equipment and the presence of lead where the food is grown. Some commonly adulterated spices include turmeric, paprika, marigold, and curry powder, which can contain more than 2 μg/g lead and increase BLLs of children that ingest them.

The scale of the problem

The adulteration of spices has been identified in South Asian countries, as well as in Georgia and North Africa. In Bangladesh, for example, pigment is added to turmeric root at commercial polishing mills to make its colour more vibrant, and turmeric consumption has been linked to elevated BLLs. One estimate suggests that daily use of contaminated spices may result in a 6-10 ug/dL rise of BLLs.

The tractability of reducing this source

A clear way to reduce lead-contaminated spices is to improve enforcement of regulatory controls. Effective regulation appears challenging – turmeric adulteration is already legally prohibited in many areas, but the turmeric industry is dominated mostly by small, informal enterprises, where few companies have the incentive to comply with regulations. However, an intervention in Bangladesh suggests promising tractability. After a study showing high levels of lead in turmeric in Bangladesh, researchers supported the Bangladesh Food Safety Authority to reduce lead levels through monitoring, fines, and education. Over a 1-year period this apparently substantially reduced lead levels in spices, though its longer-term impact is yet to be evaluated.

Another approach could involve bans on lead pigments, which would address a major source of lead in paint and plastics, as well as spices. The EU has successfully introduced a ban on the sale of lead pigments in the EU market, but it is so far unclear how achievable or enforceable this would be in LMICs.

Lead-containing cookware, cans, and ceramics

Where it’s a problem

Lead can leach into foods stored or cooked in lead-containing cookware. Lead releases when heated, and leaches more when low-pH food (like tomatoes) is cooked. Examples of lead-containing cookware being used in LMICs are locally-made cookware, lead-soldered cans, and lead-glazed ceramics.

Locally-made aluminium cookware contains lead usually passed on from the informal recycling of ULABs or other scrap metals. Lead-soldered side-seam cans contain lead as they are usually recycled or repaired with lead solder. Lead in ceramics is due to the traditional use of lead glazes for a shiny and bright finish.

The scale of the problem

Inexpensive aluminium has been found in at least 20 countries to have dangerous levels of lead, and lead-soldered cans are still available in Mexico where lead content has been found to be up to 3.70 mg/kg per can, as well in Bangladesh; and are associated with elevated BLLs. Meanwhile, lead-glazed pottery is found to be a significant source of lead exposure in Latin America and Mexico, where at least a million children were found to have elevated BLLs above 5 μg/dL.

The tractability of reducing this source

With regards to lead-containing cookware, there appear to be no regulatory standards set in many countries. Even if present, they may be difficult to enforce since lead-containing ceramics and cookware are typically made in the informal sector by smaller distributed manufacturers. Lead-soldered cans have a similar problem; they can be difficult to regulate since they are usually made by household recycling of tin cans.

For glazed pottery, Pure Earth wrote that regulation may be slightly more difficult due to the indigenous potters being a high-value political constituency and that educational interventions and assistance with alternatives may be more feasible. One group working on this in Mexico is Barro Aprobado, a project of Pure Earth’s with efforts on supporting pottery communities to encourage lead-free productions.

Poorly controlled lead mining and smelting operations

Where it’s a problem

Global mined lead production has approximately doubled since the 90s. Lead-related occupations, such as mining and smelting, may contaminate the environment and expose their workers to high levels of lead, who could carry lead around and extend this exposure to their communities and families. Higher lead exposure more likely occurs as a result when lead mining and smelting operations are poorly controlled.

The scale of the problem

Currently, poorly controlled lead mining and smelting operations appear to be most significant in African communities, especially in the South, where there have already been several lead poisoning outbreaks that have occurred in both informal and formal sectors. Higher BLLs are found to be associated with children living in the vicinity of lead smelters and mines. A study found children in towns near lead mines in South Africa to have 85-98% of children with BLLs ≥10 μg/dl, with elevated BLLs associated with having a father working in the mine.

The tractability of reducing this source

Mining companies and the government are key stakeholders in mining in Africa. While there currently appear to be environmental protection laws in place that can reduce environmental contamination, it is uncertain whether strict personal hygiene measures are in place, which can reduce lead exposure in the workplace. Further, because of the presence of the informal mining sector, small-scale mining may largely be unregulated. Separate from regulation, groups like Pure Earth and the World Bank have also worked with local governments in educational and cleanup efforts in severely contaminated neighbourhoods.

Electronic waste (e-waste) recycling

Where it’s a problem

Lead is commonly added to plastic electrical wire insulation in electronic equipment to improve durability. It’s found in some types of e-waste to weigh up to about 2.9 g/kg. The unmanaged scavenging of e-waste has become a common income source for low-income communities near landfills, which try to recover lead and other metals from the e-waste (such as copper and gold) for extraction and recycling. Informal recycling activities (e.g. crude methods, open-pit acid baths, or processes incorporating burning) could cause severe toxic exposure. Apart from exposing workers to toxic products, these activities also contaminate the surrounding environment.

The scale of the problem

E-waste is reported to be the world’s fastest-growing waste stream. In 2019, only 17.4% of e-waste reached formal management or recycling systems. About 80% of collected e-waste is shipped to LMICs, often illegally. With around 20 to 25 million tons of e-waste being produced annually in the United States, Europe, and Australasia, that could be as high as 1.6 to 2 million tons of e-waste being transported to LMICs.

E-waste is also still produced by LMICs, though there’s less available data. In 2007, India and Thailand are estimated to have produced 0.33 and 0.1 million tons of e-waste respectively.

Thousands of informal workers, ~18 million children and adolescents, and ~12.9 million women may be at risk from adverse health outcomes linked to e-waste recycling. It’s unclear how much of the health risks from e-waste are due to lead, but notably, a large portion of e-waste contains lead: between 1994 and 2003, about 500 million personal computers contained significantly more lead than other metals i.e. cadmium and mercury.

The tractability of reducing this source

The issue of e-waste exists despite the existence of guidelines and laws (such as those provisions from the Basel Convention) already prohibiting informal e-waste management. This may be because the Convention only requires “prior informed consent” be obtained before exporting wastes to a developing country, which can be easily disregarded. Companies would need to follow health and safety rules or use pollution-control technologies that reduce the health and environmental hazards of handling e-waste.

One way e-waste facilities could be better managed is for informal e-waste facilities to formalise (become larger and better-controlled) facilities, however, this seems to be expensive and it is unclear how feasible this would be.

Other preventative ways to reduce e-waste lead exposure can include awareness and education for e-waste workers on potential health hazards and better health and safety procedures around recycling. Incentivizing companies to manufacture electronics without harmful substances and easy-to-disassemble components is also one possible but probably less practical solution.

Lead in water systems

Where it’s a problem

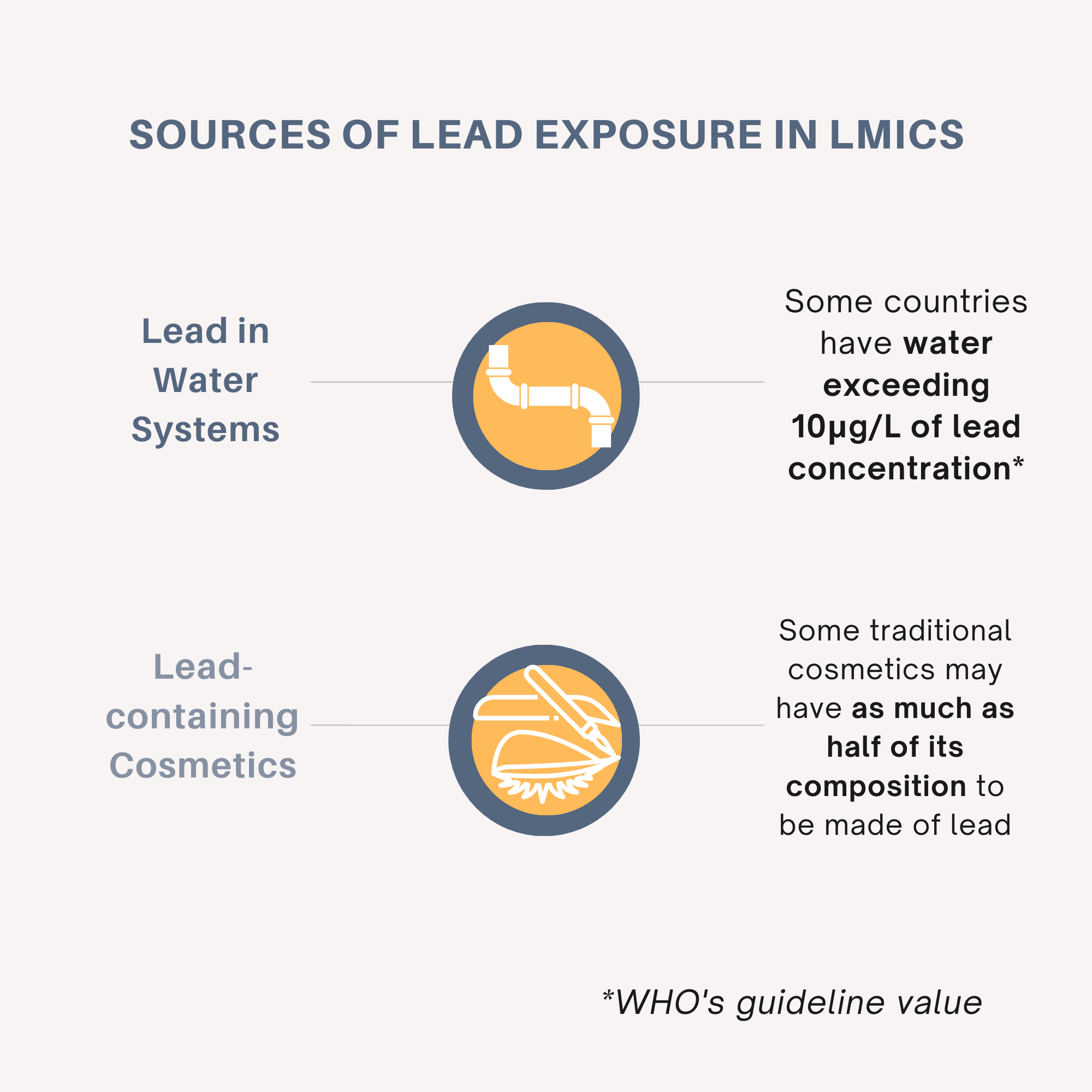

Lead is rarely naturally present in tap water but instead contaminates water when plumbing materials that contain lead, such as pipes, solder, or brass fittings, corrode. In LMICs, these can include lead-containing materials used in community water systems, such as boreholes (wells) with hand pumps and public taps.

Polyvinyl chloride (PVC) pipes are also found to be sources of lead contamination in water in LMICs. They’re generally favoured by pipe producers due to their long-lasting material and low cost and are used with lead stabilisers to improve their durability and resistance to heat and sunlight. Lead compounds from these stabilisers could be released into drinking water and cause elevated BLLs. PVC pipes have been found to be more lead-releasing than pipes made with other materials.

The scale of the problem

The WHO has a guideline value of 10μg/L for lead concentration in water. Some studies conducted in West Africa have found communities with water that exceeds this value, and attribute high lead contamination to plumbing fixtures such as brass taps. In India, about 50% of PVC pipes are used for transporting drinking water and plumbing.

The tractability of reducing this source

A direct way to reduce lead exposure from currently installed pipes is to remove and replace lead pipes and plumbing and fittings containing lead with non-lead metals, but this is costly. The lead content of new piping and plumbing can also be regulated. For instance, PVC pipes were set to be regulated in India in 2019, but some of their mandates have recently been challenged due to the capital investment needed.

Other interventions can include using lead-rated water filtration systems or in situ electrochemical passivation (sealing off lead in the pipes to prevent corrosion), however, these have not been widely investigated yet.

Lead-containing cosmetics

Where it’s a problem

Various types of cosmetics, usually traditional cosmetics or remedies, are sources of lead exposure in LMICs. Some examples of this are sindoor, a traditional cosmetic powder worn by women in India, and kohl (or surma), a widely used traditional cosmetic eyeliner worn by men, women, and children in countries from South Asia, the Middle East, and North Africa. Similar to kohl in Nigeria is a folk remedy called tiro, which is applied to the infant’s eyelids to promote visual development.

The scale of the problem

In India, children who use these cosmetics have higher BLLs than those who don’t. Typically, lead in cosmetic products is limited to 10-20 parts per million (ppm), but products like Kohl are found to have high concentrations of lead (as much as half of its chemical composition), generally being made by grinding lead sulphide.

The tractability of reducing this source

In countries like the US and the UK, cosmetics are regulated by organisations like The Food and Drug Administration (FDA) and the Cosmetic, Toiletry and Perfumery Association (CTPA). While some regulations exist in LMICs, they appear to be poorly enforced and difficult to regulate as the industry is mostly composed of small manufacturers like street vendors and traditional healers. Further, as traditional cosmetics, some have strong beliefs attached to them.

Lack of awareness is also contributory to the issue – a study noted that even physicians and healthcare workers in LMICs may be unaware of possible lead uptake from these sources, so educational efforts may be valuable.

LEEP is exploring work on other sources of lead exposure

LEEP is committed to reducing lead poisoning to improve the health, wellbeing, and potential of children worldwide. We currently focus on lead paint regulation due to its strong evidence base for impact, and over the coming year we plan to explore effective interventions to reduce lead expsoure from other sources.

Helpful resources

ABOUT THE AUTHOR

Kirsten Angeles

Kirsten is a graduating student from BS Health Sciences at the Ateneo de Manila University in the Philippines. She has interned at LEEP since January 2022 and is interested in effective altruism (EA), EA community building, global health and development, and longtermism. She was the former President of Effective Altruism Blue, has interned at EpiMetrics, Inc., a Health Equity Research organization in the Philippines, and is a contractor for the Centre for Effective Altruism. She can be contacted via [email protected] and https://www.linkedin.com/in/kirstenangeles/ . You can read more about her on her website.